Overview of Tosoh CeramicsGuide

CompanyCompany Information

Established April 2, 1988.

Tosoh Ceramics was created

as a fully owned subsidiary of Tosoh Corporation.

Headquarters and Plant

- Headquarters:

- 2 Iwasekoshi-machi, Toyama City, Toyama Prefecture 931-8371

(5 min. walk from Iwasehama Station on Toyamakō Line)

- Toyama Plant:

- 2 Iwasekoshi-machi, Toyama City, Toyama Prefecture 931-8371

Scroll horizontally

-

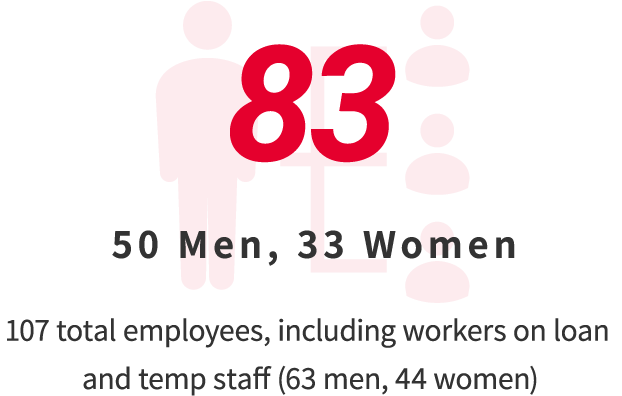

Employees

Direct-Hire Employees, as of April 1, 2024

-

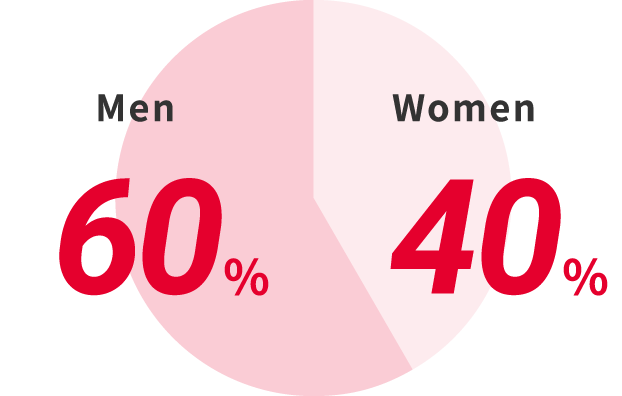

Gender Breakdown

Direct-Hire Employees, as of April 1, 2024

-

Average Age

Direct-Hire Employees, as of April 1, 2024

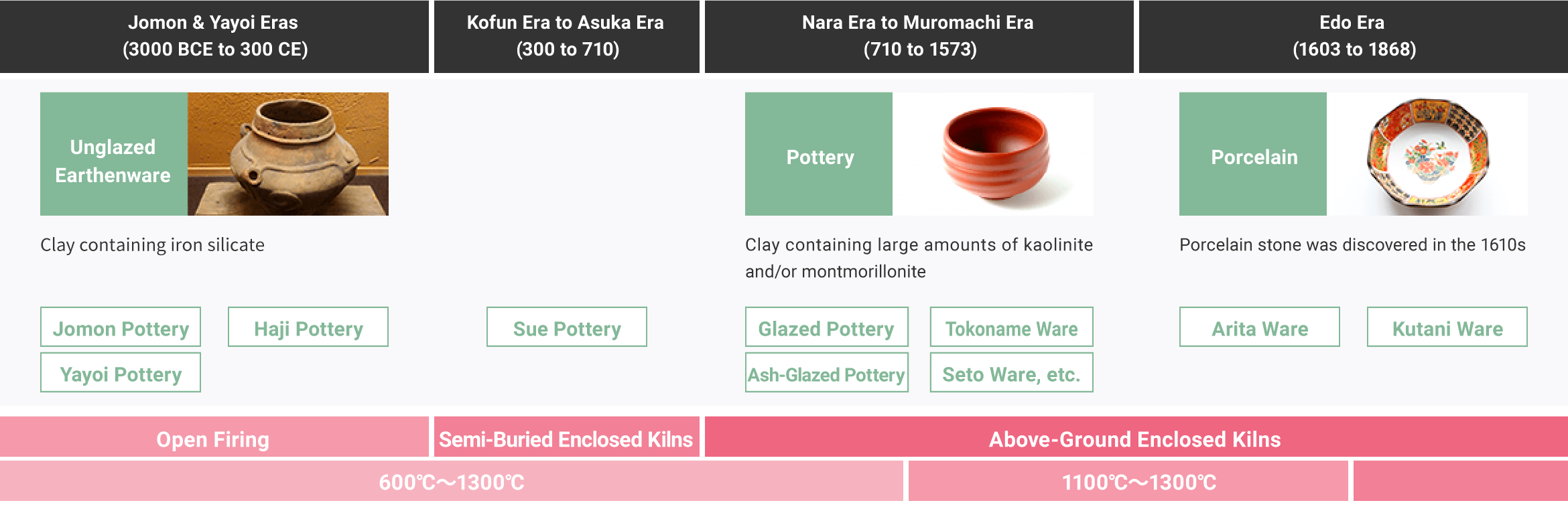

What is ceramics?

An advanced material from 10,000 years ago.

Ceramics are one of the three main categories of industrial materials, alongside metals and plastics.

The history of ceramics stretches back 10,000 years,

playing major rules in culture and everyday life since the dawn of human civilization.

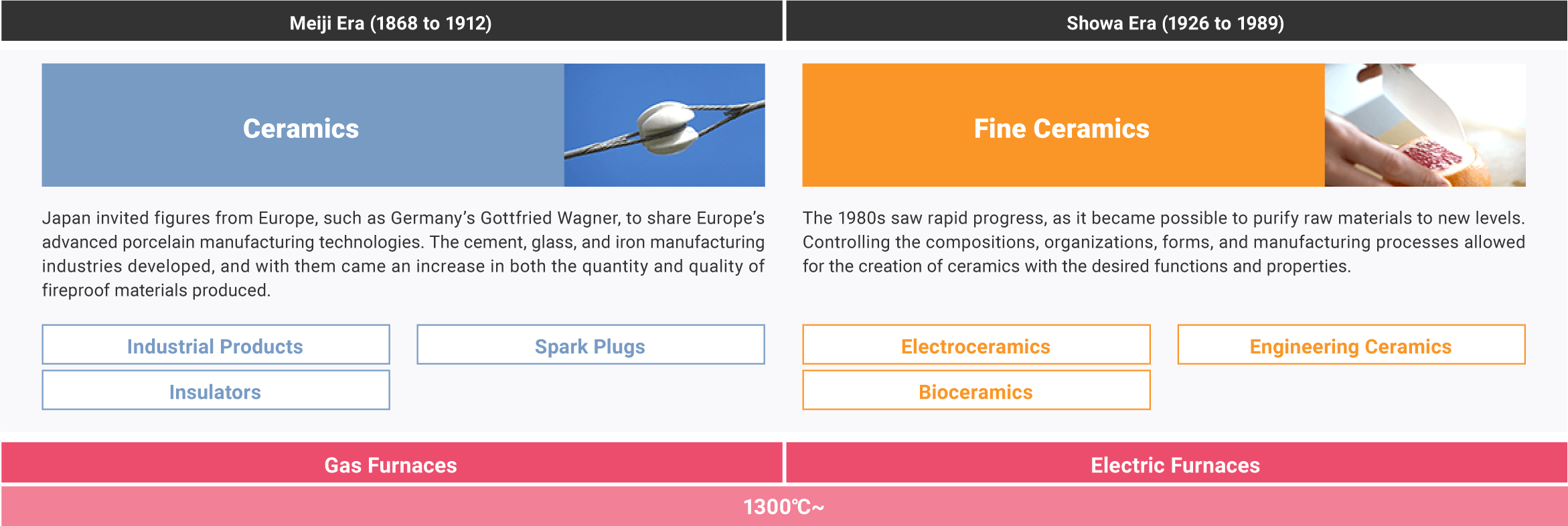

History of Ceramics

The Origins of Ceramics

Scroll horizontally

Early Modern Era to Today

Scroll horizontally

The Diverse Functional Properties of Fine Ceramics

According to the Ceramic Society of Japan, ceramics are “non-metallic, inorganic solid materials produced through artificial processing.” Additionally, according to JIS R 1600:2011 (Glossary of Terms Related to Fine Ceramics), fine ceramics are defined as “primarily non-metallic, inorganic materials with new functions or properties, with carefully controlled chemical compositions, crystalline structures, microtextured organizations/grain boundaries, forms, and manufacturing processes.”

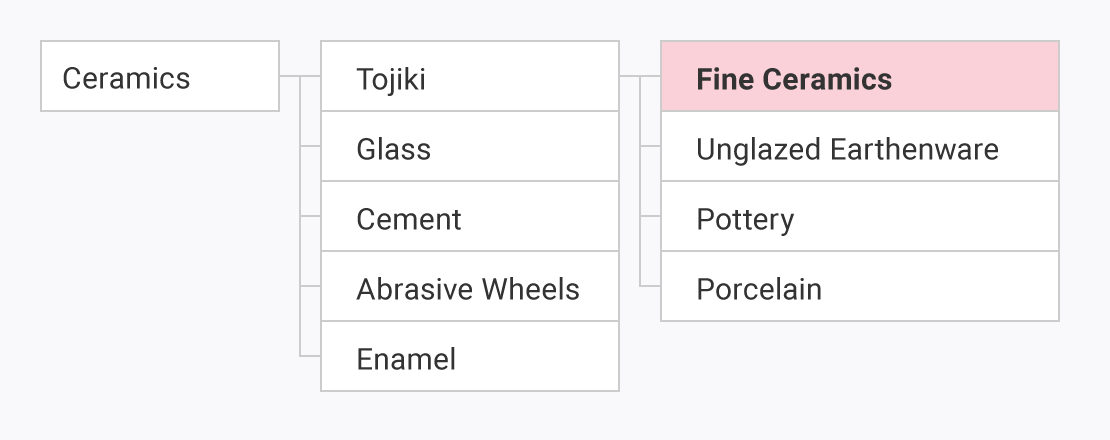

Categories of Ceramics

Scroll horizontally

Main Types of Fine Ceramics

Scroll horizontally

| Alumina | Al2O3 | Aluminum oxide. One of the most commonly used ceramic materials for fine ceramics. |

|---|---|---|

| Zirconia | ZrO2 | Zirconium oxide. The strongest and toughest fine ceramic material. |

| Aluminum Nitride | AlN | With its excellent thermal conductivity, this is often used as packaging material for semiconductor components and other applications requiring heat radiation. |

| Silicon Carbide | SiC | Does not naturally occur. An exceptional thermally resistant material: it maintains its strength even at high temperatures, and is light yet resists corrosion. |

| Silicon Nitride | Si3N4 | A material with outstanding toughness even at high temperatures and exceptional thermal shock resistance, and which is corrosion-resistant yet lightweight. Used as a material for engine components. |

| Forsterite | 2Mg・SiO2 | Features excellent high-temperature insulation properties, with low microwave loss. Used in components for electrical and electronic products. |

| Cordierite | 2MgO・2Al2O3・ 5SiO2 |

Its particularly low thermal expansion gives this excellent thermal shock resistance. A porous, fireproof material. |

| Barium Titanate | BaTiO3 | With some of the highest electrical permittivity of any ceramic material, this is excellent at storing electrical charges, leading to its use in capacitors. |

| Lead Zirconate Titanate | PZT | Run an electric signal through this piezoelectric material to cause it to vibrate, or use its properties to convert vibrations into an electric signal. |

| Ferrite | M2+O・Fe2O3 | A magnetic ceramic material with high magnetic permeability, as well as significant electrical resistance and abrasion resistance. |

| Mullite | 3Al2O3·2SiO2 | This heat-resistant material has excellent creep resistance, as well as superb heat tolerance and thermal shock resistance. |

The Possibilities of Ceramics

Ceramics offer a diverse variety of uses, both in products that are a crucial part of everyday life, and in solutions to resource, energy, and environmental issues. As time goes on, the roles they play are expected to only grow more important.

Fields Where Fine Ceramics Are Used

-

Machinery, Aviation,

and Space

Exploration -

Chemicals and

the Environment -

Everyday Life

and Sports -

Energy -

Electronics,

Information, and

Communications -

Biotech

and

Medical Care

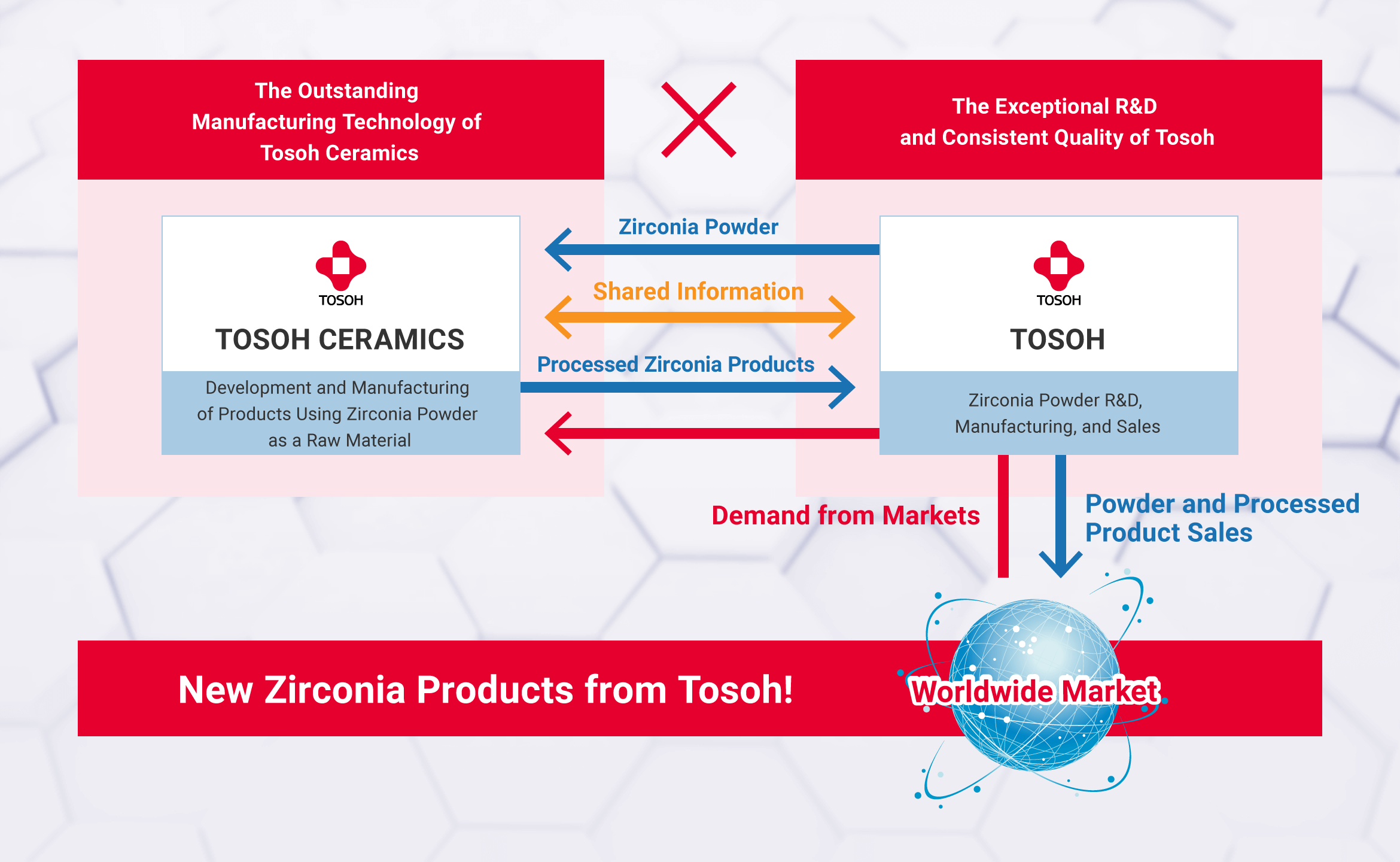

Our StrengthThe Tosoh Ceramics Advantage

Creating Industry-Leading New Products

with Our World-Class Technical Capabilities

Our parent company Tosoh boasts a leading share of the worldwide market for high-purity,

high-quality zirconia powder manufacturing and sales. We use this Tosoh zirconia powder as a raw material for the development and manufacturing of

outstanding processed products — one of our greatest strengths.

Delivering High-Quality Compounds and Precision Processed Products

High-Purity, High-Quality Zirconia Powder from Tosoh — the Choice of Clients Worldwide

- 1We have overcome the brittleness that can be a downside of ceramics, achieving extraordinary toughness and bending strength.

- 2Our colored zirconia lineup is available in a variety of hues.

- 3We boast the top market share worldwide for zirconia used as dental materials.

High-Quality Compounds Made Possible through Our Technical Capabilities

Powdered ceramics created through R&D at Tosoh serve as the foundation for our production of high-quality ceramic compounds for injection molding.

Creating New Products

Tosoh shares the latest updates about worldwide needs with us, and we use our technical capabilities to take advantage of the properties of the powders they have developed, to bring new products to the market.

SceneProduct Applications

Tosoh Ceramics, All around You

The ceramic products we manufacture can be found all throughout everyday life: in cars and mobile devices, in medical components, and more.

Our products play myriad roles, both seen and unseen, to support society.

Just like the people who work at Tosoh Ceramics, our products are strong yet friendly.